Samsung Display research center is accelerating the development of QNED as

the next-generation display following OLED.

The reason Samsung Display is developing QNED

as part of its large-size display business is that it is the only display that

can produce the image quality that Samsung Display's biggest customer, Samsung

Electronics, can satisfy.

Samsung Electronics' TV business direction,

which has the world's No. 1 TV market share, is to use QD to make color gamut

better than OLED, and to use a display that can maximize HDR performance with

high luminance and excellent gradation characteristics on a bright screen.

The only display that can satisfy the needs of

Samsung Electronics is QNED.

|

Items

|

QNED

|

OLED

|

Mini-LED LCD

|

|

Color gamut

|

best

|

better

|

best

|

|

HDR

|

best

|

better

|

better

|

|

Luminance

|

best

|

better

|

better

|

|

Contrast ratio

|

best

|

best

|

better

|

|

Motion blur

|

best

|

best

|

good

|

QNED is a self-luminous display and because it

uses QD, it has the best color gamut, HDR, luminance, contrast ratio, and

motion blur, etc., and is a product expected by Samsung Electronics.

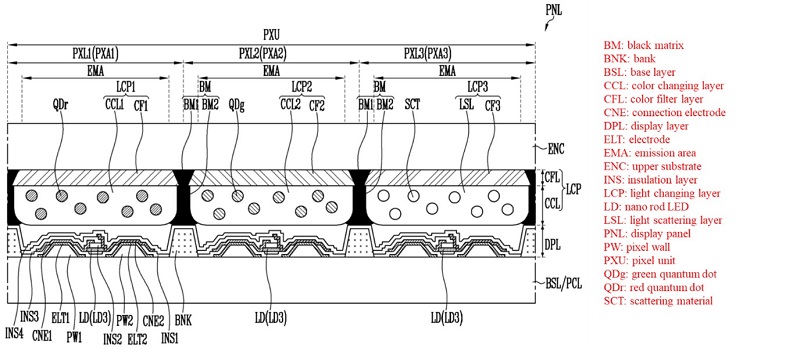

It can be confirmed by the structure that QNED

is the display with the best characteristics. QNED consists of a pixel layer

with a nano-rod LED on the TFT structure of 3T1C used in large OLEDs, and a

color conversion layer consisting of QD and CF (color filter) on top.

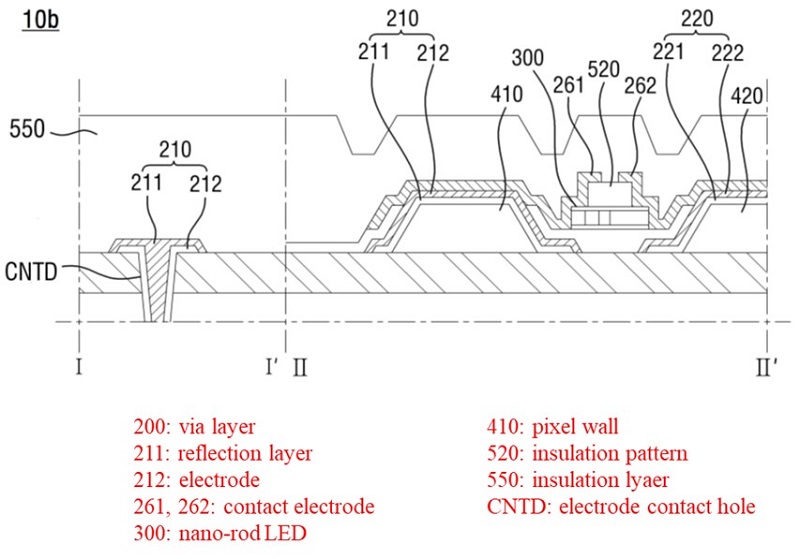

In OLED, electrodes (cathode and anode) and electrode

line for transmitting a signal to a pixel are located above and below the light

emitting material, whereas in QNED, both the signal transmitting electrode

(pixel electrode) and electrode line are located on the same plane. In addition

to the pixel electrode, the QNED additionally includes a reflective electrode

to increase light output efficiency. The pixel electrode serves as an alignment

electrode for aligning the nano-rod LED.

< QNED section structure >

< QNED pixel structure >

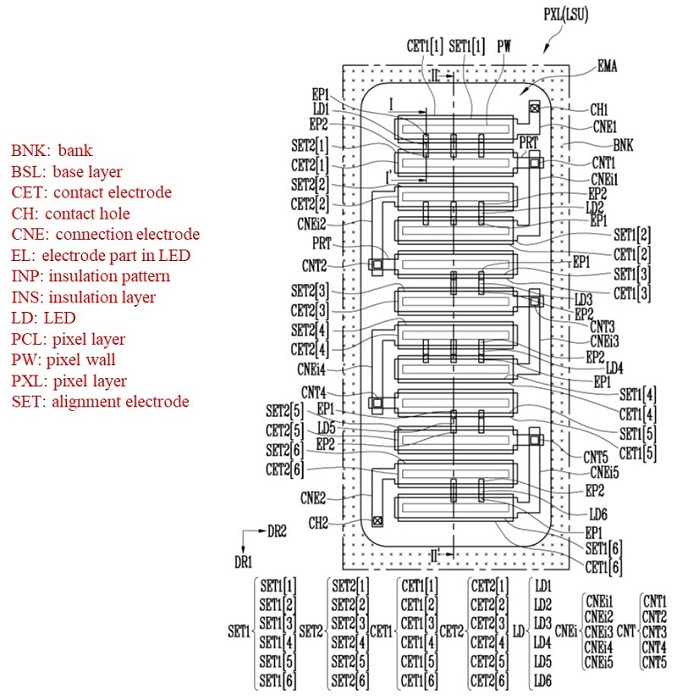

< QNED pixel planar structure >

Looking at the planar structure of a QNED

pixel, a plurality of pixel electrodes are connected in series in one pixel,

and a nano-rod LED is positioned between the pixel electrodes. The pixel

electrode is on the pixel

wall (PW) formed of an

insulating material, and each pixel is surrounded by a bank (BNK) to separate

regions.

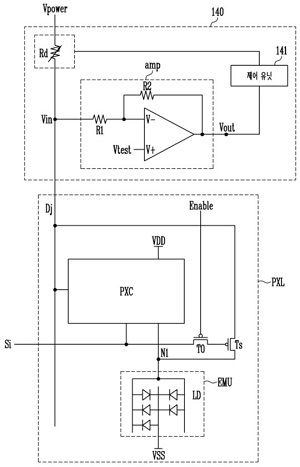

The core technology of QNED is driving

technology and sensing technology.

The driving technology includes a driving

technique for aligning nano-rod LEDs and a driving technique for uniformly

controlling pixels that may have a deviation in the number of nano-rod LEDs.

The alignment circuit includes switching elements for each pixel, and the

switching element applies an alignment signal to the pixel. The alignment state

of the nano-rod LED is determined depending on which alignment signal is given

to each pixel.

< Drive circuit for alignment >

< Sensing transistor for checking alignment >

The most important driving technology is a

technology that supplies current to each pixel so that the luminance can be

uniform across the entire screen even if the number of nano-rod LEDs per pixel

is different. It is a method of controlling each pixel based on the data read

from the sensing transistor.

[QNED Technology Completion Analysis Report]

details the sensing transistor, sensing wiring, and sensing signals that can

check the nano-rod LED alignment status on the panel.

As sensing technology, there are sensing

technology (sensing transistor) designed inside QNED and sensing technology

used in QNED manufacturing. The sensing technology used to manufacture QNEDs is

inherent in inkjet systems. There are three sensing technologies in the inkjet

system: the number of nano-rod LEDs in the ink and the viscosity analysis of

the solvent, the analysis of the number of nano-rod LEDs sprayed on the panel,

and the analysis of the nano-rod LED alignment state. < Inkjet system configuration >

QNED has already proven that 4K 65 inches can

be driven two years ago. Samsung Display is concentrating on finishing work to

secure the screen uniformity of QNED. |