At IMID 2022 held in BEXCO, Busan, from August 23rd to the 26th, ETRI held an exhibition and presentation, ‘Development of QD-OLED Technology with Fine Quantum Dot Pixel Array using Inkjet Printing Process’.

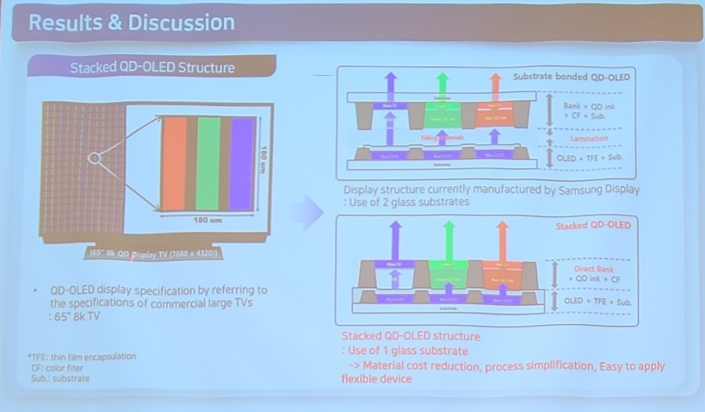

<Stacked QD-OLED structure/ ETRI> Two glass substrates are used in the QD-OLED produced by Samsung Display, but the ‘Stacked QD-OLED’ developed by ETRI has a structure in which the glass with the QD color conversion layer is removed. In the stacked OLED, TFE and BM are formed on the light emitting layer, and the QD color conversion layer is formed by the inkjet printing process instead of the lamination process. The ‘Stacked QD-OLED’ structure has advantages such as material cost reduction and process simplification compared to the existing method. ETRI explained that there are advantages of material cost reduction and process simplification compared to the existing process through this, and the thickness of the QD color conversion layer can be made thicker than before, resulting in a higher color conversion rate and less blue light leakage.

Meanwhile, ETRI collaborated with Kosan Tech for inkjet module head, Duksan Neolux for black bank material, and Chem e for QD material to develop ‘Stacked QD-OLED’.

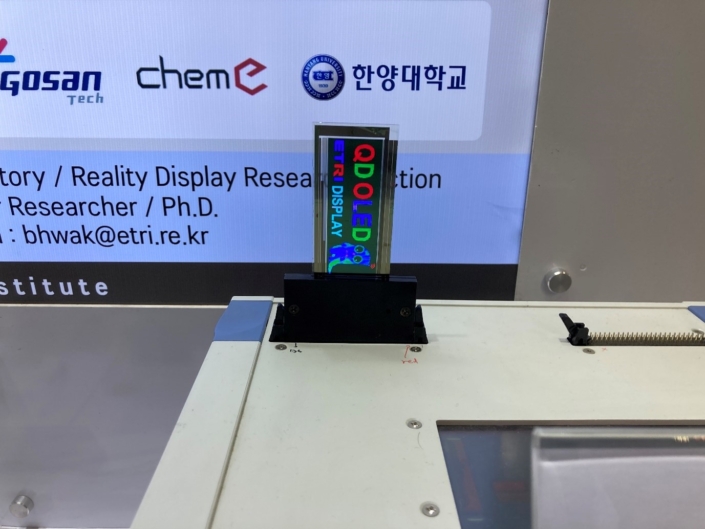

<‘Stacked QD-OLED’ Developed by ETRI>  OLED Display Report Sample Download OLED Display Report Sample Download |