Special Report

Display Application Technology Development Trend of Quantum Dot Report

₩0

July 17, 2024

PDF(95P)Introduction

Quantum Dot (QD) technology is attracting attention in the display industry due to various issues such as utilizing QD films, combining mini LEDs and QD, commercializing Cd-free QD, developing Perovskite QD, and research and development for QD-LED next-generation displays. These developments have led to improved lifespan and stability, development of eco-friendly materials, high efficiency and low cost, application of ultra-high resolution displays, and expansion of applications, brightening the future of the display industry.

QD technology is leading the premium TV market by significantly enhancing the image quality of LCD TVs and combining them with mini LED technology. QD-LED in light-emitting devices has been developed for commercialization in recent years. QD-LED is an important step in competing with OLEDs, as it announced full-color QD-LED display prototypes in Korea, China, and Japan.

Display Application Technology Development Trend of Quantum Dot Report, published by UBI Research, covers the following:

1. Apply color conversion technology to the display

2. Application of color conversion technology in pixels to microdisplay

3. Device Structure and Process Development Trends of QD-LEDs

4. Trends in QD-LED Display Development

One particularly promising aspect of Quantum Dot technology is the color conversion device, with Perovskite-based QD standing out due to its high light efficiency and narrow light emission spectrum. Ongoing research is exploring various approaches to enhance the stability of Perovskite QD, a technology that is expected to significantly improve the color reproduction rate of 4K and 8K ultra-high resolution displays in the near future.

The development of Cd-free QD is gaining momentum, driven by environmental and health concerns. Notably, indium oxide (InP)–based QD has been successfully commercialized and applied to Samsung’s latest QLED TVs and QD OLED TVs. This development is significant as it demonstrates that Cd-free QD can match the performance of existing Cd-based QDs while offering the added advantage of being eco-friendly.

Contents

1.1 History of Quantum Dot Development

1.2 CdSe Quantum Dot

1.3 Non-Cd Quantum Dot

1.4 Perovskite Quantum Dot

1.5 Summary of characteristics of various QDs

1.6ⅠⅢ Ⅳ Quantum Dot

2. Application to Color Conversion Devices

2.1 QD as a color conversion material

2.2 Application to LCD backlight

2-2-1 Application forms in edge-lit backlight

2-2-2 Application forms in direct-lit backlight

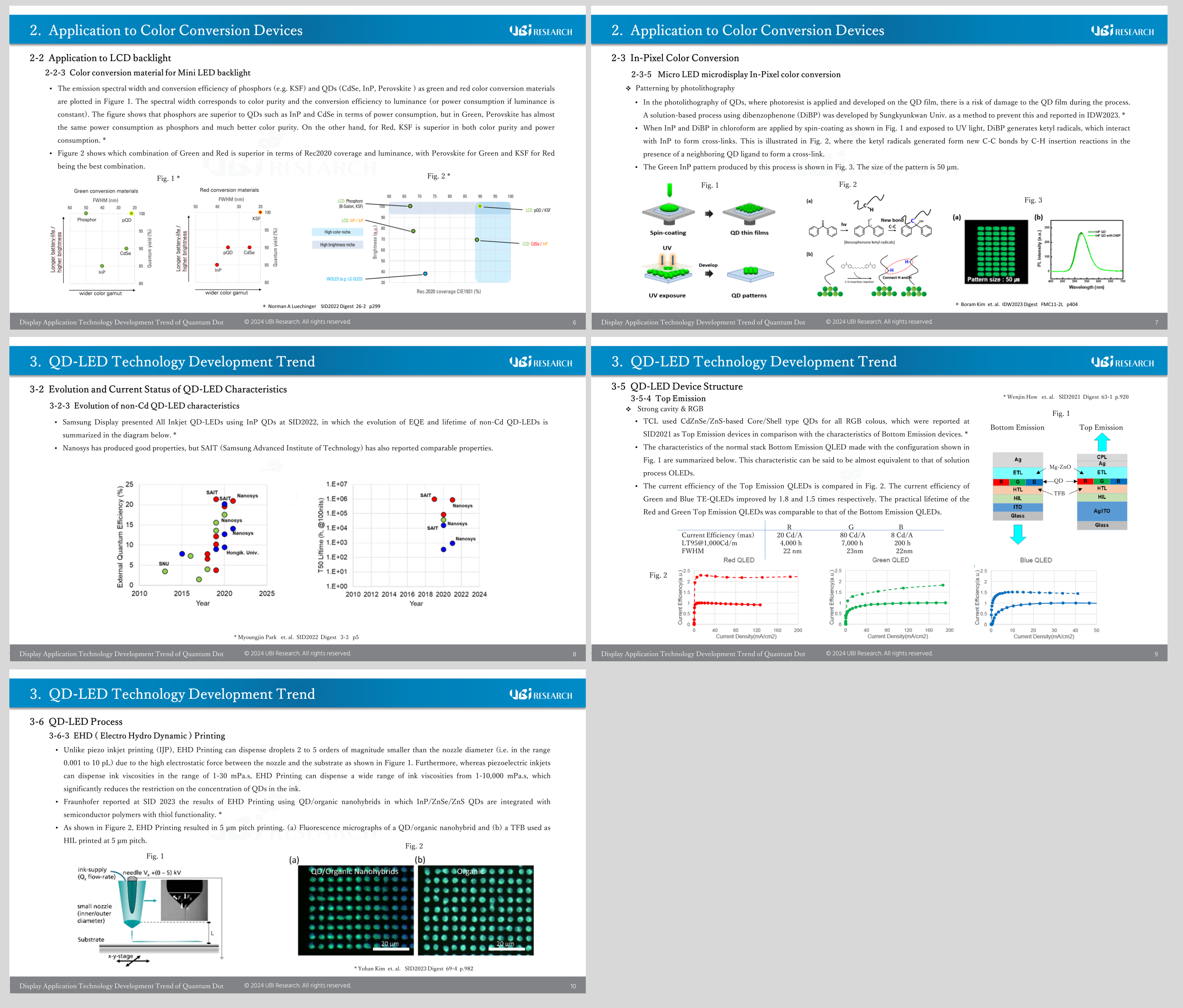

2-2-3 Color conversion material for Mini LED backlight

2-2-4 Mini LED LCD with Perovskite QDs

2.3 In-Pixel Color Conversion

2-3-1 Summary

2-3-2 Practical example of In-Pixel color conversion : QD OLED

2-3-3 Challenges and countermeasures in In-Pixel color conversion

2-3-4 QD patterning process

2-3-5 Micro LED microdisplay In-Pixel color conversion

2.4 Prototype example of In-Pixel color conversion for Micro LED microdisplay

2-4-1 Sharp

2-4-2 PlayNitride

2-4-3 Mojo Vision

2-5 Micro LED microdisplay color conversion application summary

3. QD-LED Technology Development Trend

3.1 Summary

3.2 Evolution and Current Status of QD-LED Characteristics

3-2-1 Overview

3-2-2 Comparison of non-Cd QD-LEDs and Cd QD-LEDs characteristics

3-2-3 Evolution of non-Cd QD-LED characteristics

3-2-4 Degradation factors for QD-LEDs

3.3 Development of Blue QD-LED

3-3-1 ZnSe/ZnS QD-LEDs at longer wavelength

3-3-2 Reactivity-controlled epitaxial growth of ZnSe/ZnS QD-LEDs at longer wavelength

3-3-3 Longer wavelengths and further characteristics improvement of ZnSe/ZnS QD-LED

3-3-4 Core/Shell structural design for improved characteristics

3-3-5 Improved characteristics through QD protection technology

3.4 Development of Non-Cd Red QD-LEDs

3-4-1 Improving the characteristics of non-Cd Red QD-LEDs through device design

3-4-2 Lifetime analysis of non-Cd Red QD-LEDs

3.5 QD-LED Device Structure

3-5-1 Inverted

3-5-2 ZnO ETL Layer

3-5-3 New HTL Layer

3-5-4 Top Emission

3-5-5 Tandem

3-5-6 Full Colorization by Meta surface

3-5-7 Towards further performance improvements of QD-LED in the future

3.6 QD-LED Process

3-6-1 Spin Coating

3-6-2 Inkjet Printing

3-6-3 EHD Printing

3-6-4 UV Lithography

3-6-5 Transfer Micro Contact Printing

3.7 QD-LED Display Prototype

3-7-1 BOE

3-7-2 Sharp

3-7-3 Samsung Display

3.8 White Luminescent QD-LED

3.9 Perovskite QD-LED

3-9-1 Evolution of EQE

3-9-2 EQE improvement through ligand exchange

3-9-3 Performance improvement by ETL

3-9-4 Issues for the future

3-9-5 Challenges and countermeasures : increasing the efficiency of Blue Perovskite

Report Sample

Previous Report Status

Related Products

-

Latest OLED Technology Trend Report

₩3,500,000September 15, 2020

PDF(133P)The “Latest OLED Technology Trend Report” analyzed the research presented by display companies, research institutes, and universities in SID, IMID, IDW from 2016 to 2020, and carefully selected and organized only the technology used in OLED manufacturing and the technology deemed applicable in the future.

It was compiled by Urabe (former Sony OLED development team leader/development director), a senior analyst at UBI Research.

The report will be a guideline that shows OLED developers the goals and directions of development by technology. -

Latest Technology Development Trends for OLED and QD-LED

₩5,000,000August 29, 2021

PDF(187P)The “Latest Technology Development Trends for OLED and QD-LED” report published this time contains the latest technology trends that show the current state of evolving OLED and the future evolution direction.

In addition, the latest technological trends related to QD-LED, which is called next-generation display technology following OLED, are also included in this report. If the LED itself emits light, it will be a self-luminous device with a wide color gamut, and since the solution process is possible, the manufacturing cost can be reduced, so expectations are rising as a next-generation device. -

2025 Automotive Display Technology and Industry Trends Analysis Report

₩0February 18, 2025

PDF(217P)The automotive industry is undergoing rapid transformation beyond mere mechanical innovation, entering the era of Software-Defined Vehicles (SDVs). As autonomous driving technology and electric vehicle advancements accelerate, cars are evolving from simple transportation tools into smart devices centered around user interaction.