Special Report

QNED Technology Maturity Analysis Report

₩6,000,000

June 22, 2021

PDF(271P)Introduce

The reality of QNED (quantum dot nano-rod LED) that Samsung Display is preparing as a next-generation display has become clear.

As a result of analyzing 160 patents applied by Samsung Display, it was confirmed that the structure constituting the QNED has already been completed, and that the only remaining task is to keep the number of nano-rod LEDs arranged in the light-emitting pixel constant.

The number of aligned nano-rod LEDs per pixel, which determines the yield and image quality of QNED, is determined by the distribution of LEDs in the ink, the number of LEDs injected into the pixel, and the alignment ratio of the injected LEDs.

If the distribution of the number of nano-rod LEDs per pixel is different, there is a change in the voltage applied to each pixel, resulting in a defect.

It has been confirmed that Samsung Display has already developed a method for making the number of nano-rod LEDs per pixel constant and an algorithm that can make the luminance uniform even when the number of nano-rod LEDs is different.

In the “QNED Technology Maturity Analysis” published this time, the contents of the previous report published through analysis of 94 patents and 66 newly added patents were prepared. In addition, it has been analyzed and recorded in detail so that you can know what level Samsung Display’s QNED technology has reached.

In this report, the QNED patent number, classification table, and quantitative analysis data that have not been disclosed before are provided in Excel.

Contents

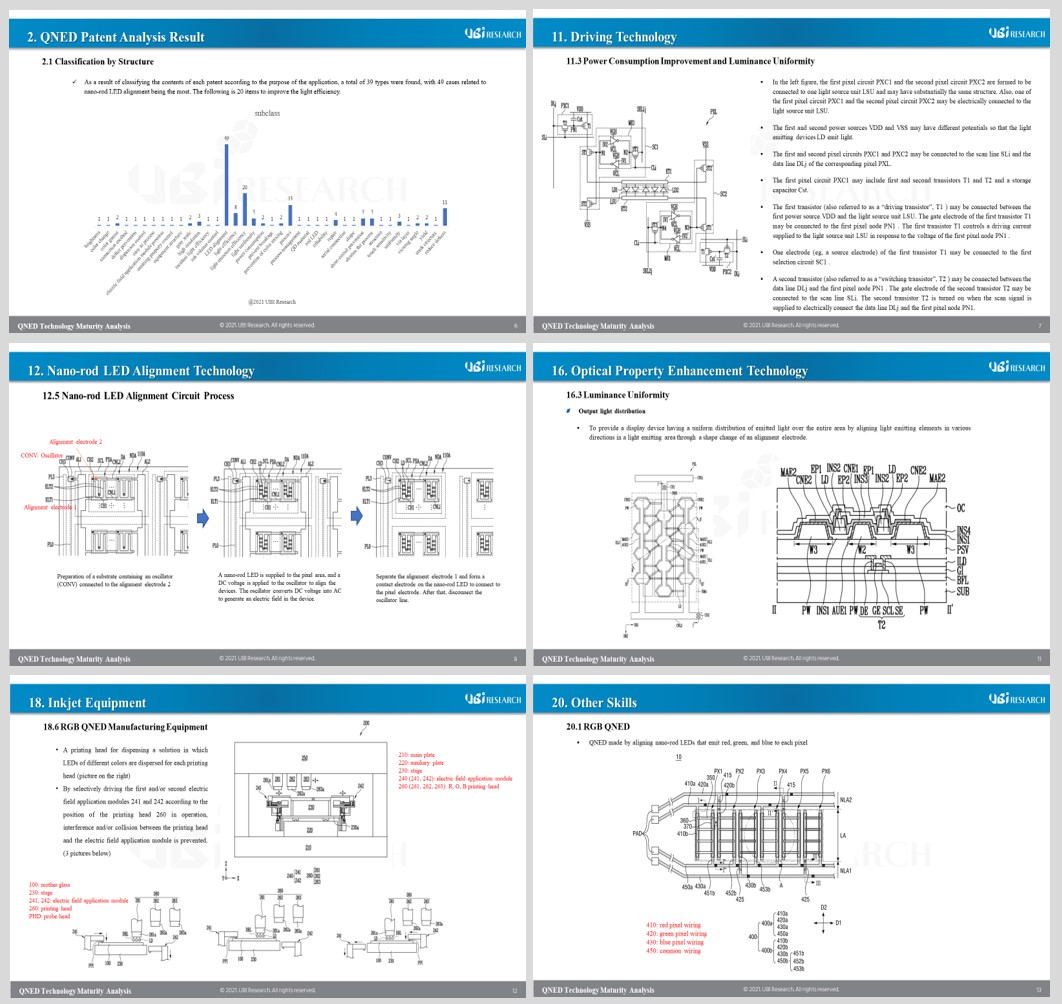

2.QNED Patent Analysis Result

2.1 Classification by Structure

2.2 Classification by Purpose

3.What is QNED?

3.1 Nano-rod LED Basic Structure

3.2 QNED Structure

3.3 QNED Emitting Principle

3.4 Nano-rod LED Alignment Principle

3.5 Mother Glass Configuration

4.Nano-rod LED Manufacturing Process

5.Nano-rod LED Ink

5.1 Nano-rod LED Solvent

5.2 Dispersants

5.3 Photodegradable Functional Groups

6.QNED Manufacturing Process

6.1 TFT Manufacturing Process

6.2 Pixel Structure and Manufacturing Process

6.3 QD-CF Structure and Manufacturing Process

6.4 Panel Structure and Assembly Process

7.Bank and Pixel Wall Structure

7.1 Bank Structure and Role

7.2 Color Bank

7.3 Structure and Function of Pixel Wall

8.Structure of Insulation Layer and Insulation Pattern

8.1 Types and Roles of Insulation Layers

8.2 Alignment Functional Insulation Layer Type

8.3 Insulating Support

8.4 Insulation Pattern Thickness

8.5 Insulation Pattern Manufacturing Method

9.Electrode Type and Structure

9.1 Electrode Types

9.2 Pixel Electrode

9.3 Alignment Electrodes

9.4 Contact Electrode

9.5 Floating Electrodes

9.6 Reflecting Electrodes

10.Circuit Structure

10.1 Circuit for QNED

10.2 2T1C Structure

10.3 7T1C Structure

10.4 3T1C Structure

10.5 Wiring Circuits

11.Driving Technology

11.1 Low Gradation Driving Method

11.2 Gamma Correction

11.3 Power Consumption Improvement and Luminance Uniformity

11.4 Improvement of Luminous Efficiency

12.Nano-rod LED Alignment Technology

12.1 Nano-rod LED Alignment Elements

12.2 Nano-rod LED Ink and Alignment Process

12.3 Nano-rod LED Alignment Waveform

12.4 Nano-rod LED Alignment Circuit

12.5 Nano-rod LED Alignment Circuit Process

12.6 Nano-rod LED Alignment Circuit and Device Structure

13. Nano-rod LED Alignment Enhancement Technology

13.1 Circular Asymmetric Electrode Arrangement Structure

13.2 Shielding Electrodes

13.3 Floating Electrodes

13.4 Protruding Electrodes

13.5 Efficient Electrode Placement Structure

13.6 Different Electrode Widths

13.7 Connecting Alignment Line

13.8 Alignment Function Insulation Layer

13.9 Alignment by External Magnetic Fields

13.10 Alignment Using Surface Energy

14.Driving Technology for Nano-rod LED Alignment

14.1 Driving Technology for Alignment

14.2 Sensing Transistor for Alignment Status Check

14.3 Sensing Line

15.Improved Nano-rod LED Properties

15.1 Improvement of Light Output Efficiency

15.2 Nano-rod LED Orienter

15.3 Nano-rod LED Couplers

15.4 Protrusion Pattern Nano-rod LED

15.5 Conical Nano-rod LEDs

15.6 Asymmetric Nano-rod LEDs

15.7 Wavelength Conversion Material Coating

15.8 Preventing Nano-rod LED Damage

15.9 Short Prevention

16.Optical Property Enhancement Technology

16.1 Light Output Efficiency

16.2 Light Incident Efficiency

16.3 Luminance Uniformity

16.4 Visibility

16.5 Viewing Angle

16.6 Color Reproducibility

16.7 High Resolution

17.Defect Resolution Technology

17.1 Short Fault Prevention

17.2 Repair Transistor

17.3 Laser Repair

17.4 Conductive Patterns for Repair

17.5 Connection Pattern for Repair

17.6 Alignment Check and Rework

18.Inkjet Equipment

18.1 Inkjet Equipment Composition

18.2 Inkjet Printer Unit

18.3 Sensing Unit

18.4 Field Applied Module

18.5 Field Generating Units

18.6 RGB QNED Manufacturing Equipment

18.7 Inkjet Equipment for Orientation

19.7T2C TFT Structure and Process

19.1 7T2C TFT and Pixel Circuit Structure

19.2 7T2C TFT and Pixel Planar Structure

19.3 7T2C TFT and Pixel Cross Section Structure

19.4 7T2C TFT and Pixel Manufacturing Process

20.Other Skills

20.1 RGB QNED

20.2 Slim QNED

20.3 Bridge Pattern

20.4 Minimizing Contact Defects

20.5 Nano-rod Vertical Array Method

20.6 Quantum Rod Arrangement

20.7 Rubbing Techniques

20.8 Touch Sensor built-in QNED

21.Conclusion

21.1 QNED Success Factors

21.2 Technical Maturity

21.3 Defect Causes and Solutions

Report Sample

Previous Report Status

Related Products

-

QNED Technical Analysis Report

₩6,000,000November 12, 2020

PDF(164P)This report consists of a detailed analysis of 94 patents filed by Samsung Display in relation to QNED, which were released by the second week of October 2020. In the first half of last year, QNED was analyzed as 41 patents, and there was a difference of about 6 months in the additional patents, but surprisingly technological progress was confirmed. The backplane of QNED is 7T2C TFT, and it was found that the oscillator for aligning the nano-rod LED and the transistor for repair are arranged together. The QNED circuit was configured similar to the TFT structure used in OLED for mobile devices. Since QNED is also a current driven device, it seems that precise control is required. Large OLED uses 3T1C structure.

-

QNED Structure and Manufacturing Technology Analysis Report

₩2,500,000May 25, 2020

PDF(61P)UBI Research published a report analyzing Samsung Display’s 41 published patents for QNED (quantum dot nanorod LED). Samsung Display is developing QNED as the next-generation display business. Reports on the QNED structure have already been issued through various channels, but the substance of the QNED has not been released. This report contains directions for the development of QNED technology, including QNED pixel structure and nanorod LED alignment principles analyzed from published patent content. In addition, a manufacturing process constructed based on the structure depicted in the patent was included.

-

Middle and Large Sized AMOLED Manufacturing Process Report Ver. 6

₩4,000,000March 8, 2024

PDF(194P)This report covers the manufacturing process of each type of TFT, including LTPO and Oxide TFT, as well as the structure and cell manufacturing process of OLEDs.

The MLA (micro lens array) formation process for enhancing the brightness of WOLED TVs and the encapsulation process for QD-OLED TVs have been added to the medium and large AMOLED manufacturing process report. Also newly added or updated are the Oxide TFT process with a reduced number of masks, and the eLEAP process and SEL’s photolithography process, which are photolithography OLED processes that have recently attracted great attention as new 8th generation substrate OLED manufacturing processes.

This report will be a must-read for display companies to understand the AMOLED manufacturing process from TFT substrate to cell manufacturing.