Special Report

QNED Technical Analysis Report

₩6,000,000

November 12, 2020

PDF(164P)Introduce

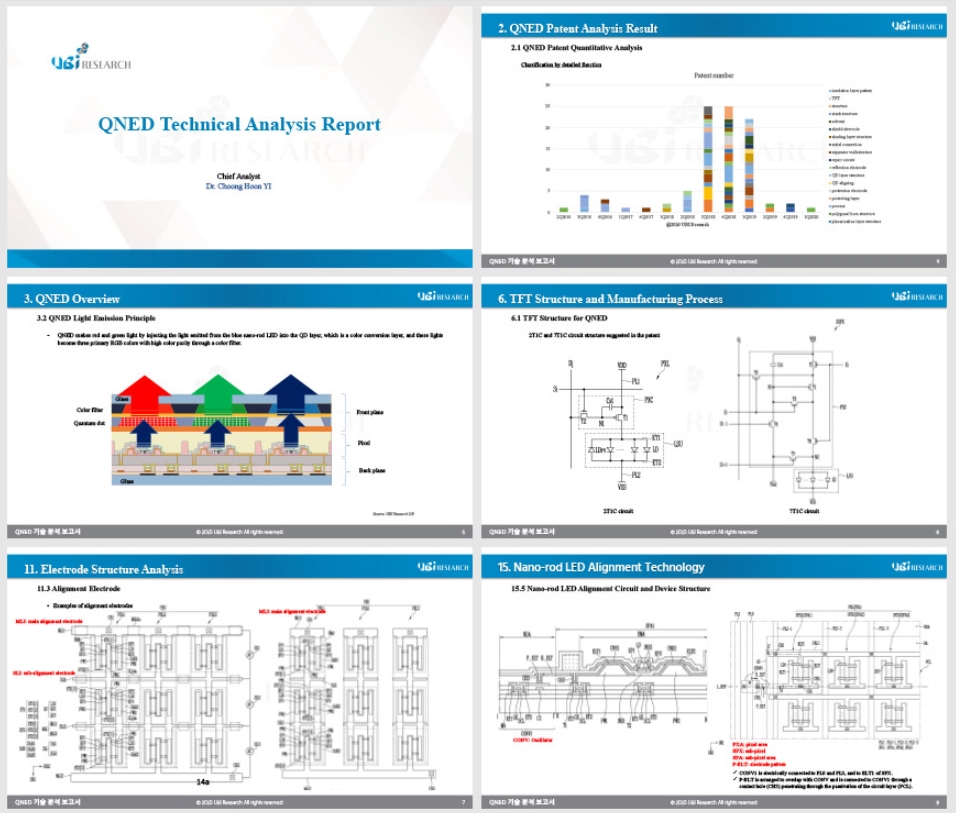

This report consists of a detailed analysis of 94 patents filed by Samsung Display in relation to QNED, which were released by the second week of October 2020. In the first half of last year, QNED was analyzed as 41 patents, and there was a difference of about 6 months in the additional patents, but surprisingly technological progress was confirmed.

The backplane of QNED is 7T2C TFT, and it was found that the oscillator for aligning the nano-rod LED and the transistor for repair are arranged together. The QNED circuit was configured similar to the TFT structure used in OLED for mobile devices. Since QNED is also a current driven device, it seems that precise control is required. Large OLED uses 3T1C structure.

Among the additionally confirmed contents, the most remarkable one is the built-in alignment transistor (oscillator). Nano-rod LEDs are dropped onto the panel in ink state and aligned by dielectrophoretic force by the electric field applied to the panel. At this time, the number of nano-rod LEDs and the pixel yield are determined according to the alignment waveform. Oscillator technology has never been used in displays.

A concern among experts regarding QNED is yield. Since about 10 to 20 nano-rod LEDs that are supposed to be arranged in a pixel are all electrically connected, a short circuit may occur in the pixel due to self-defect or misalignment of the nano-rod LED. In order to solve this problem, Samsung Display has placed a series/parallel hybrid connection wiring structure and a repair transistor. The backplane manufacturing technology is much more complex than the previously expected structure, but it has been confirmed that it has a built-in technology that can secure a yield directly related to business feasibility.

This report contains patents related to solvents for nano-rod LED inks. Viscosity control is a key technology for the conditions necessary to disperse the nano-rod LED and for good alignment after spraying. Samsung Display was using a breakthrough technology that could change the viscosity of the solvent in the process.

In addition, the configuration of the inkjet equipment was described in detail. The inkjet printer system consisted of a unit that injects nano-rod LED ink, a module that checks the position and amount of the injected ink, and a unit that senses the number of aligned nano-rod LEDs. The inkjet printer was equipped with a technology capable of correcting the ink viscosity and quantity, inkjet head position by analyzing the results evaluated in each process and feeding back to the inkjet unit.

Samsung Display started filing for QNED patents in 2016. The technology development period is only 4 years, but the level of technology confirmed as a patent filed until 2019 is expected to have no problem with investment in mass production equipment in 2021.

If you are a display expert, you can see that the quality of QNED technology is close to mass production as analyzed in this report.

Contents

Outline

1.Samsung Display’s Large Display Business Direction

1.1 Current Status of Large OLED Business for TV

1.2 Withdrawal of LCD Business and Promotion of QD-OLED Business

1.3 QD-OLED Structure and Manufacturing Technology

1.4 QD-OLED vs WRGB OLED

1.5 QNED Appearance

2.QNED Patent Analysis Result

2.1 QNED Patent Quantitative Analysis

2.2 QNED Core Technology and Related Items

3.QNED Overview

3.1 QNED Structure

3.2 QNED Light Emission Principle

3.3 Nano-rod LED

3.4 Nano-rod LED Alignment Principle

4.Nano-rod LED Structure and Manufacturing Process

4.1 Nano-rod LED Structure

4.2 Nano-rod LED Manufacturing Process

4.3 Nano-rod LED Damage Prevention

5.Nano-rod LED Ink

5.1 Nano-rod LED Solvent

5.2 Dispersant

5.3 Photodegradable Functional Groups

5.4 Device Orientation Functional Groups

6.TFT Structure and Manufacturing Process

6.1 TFT Structure for QNED

6.2 TFT Manufacturing Process

7.Pixel Structure and Manufacturing Process

7.1 Pixel Structure

7.2 Pixel Manufacturing Process

8.QD-CF Structure and Manufacturing Process

8.1 Why Use QD-CF

8.2 QD-CF Structure

8.3 QD-CF Manufacturing Process

8.4 Other QD-CF Structures

9.Assembly

9.1 Panel Structure

9.2 Panel Assembly Process

10.Circuit Structure

10.1 Circuit for QNED

10.2 Driving Circuit

10.3 Wiring Circuit

11.Electrode Structure Analysis

11.1 Electrode Type

11.2 Main Electrode

11.3 Alignment Electrode

11.4 Contact Electrode

11.5 Floating Electrode

11.6 Reflective Electrode

11.7 Efficient Electrode Arrangement Structure

12. Insulation Layer Structure Analysis

12.1 Insulation Layer Type and Role

12.2 Alignment Function Insulation Layer Type

12.3 Alignment Function Insulation Layer Thickness and Number of Alignments

13.Separation Wall Structure Analysis

13.1 Function of Separation Wall

13.2 Separation Wall Type

14.Bank Structure Analysis

14.1 Bank Structure and Function

15.Nano-rod LED Alignment Technology

15.1 Nano-rod LED Ink and Alignment Process

15.2 Nano-rod LED Alignment Waveform

15.3 Nano-rod LED Alignment Circuit

15.4 Nano-rod LED Alignment Circuit Process

15.5 Nano-rod LED Alignment Circuit and Device Structure

15.6 Nano-rod LED Alignment Enhancement Technology

16.Optical Efficiency Improvement Technology

16.1 Light Extraction Technology

16.2 light Extraction Lens

16.3 Reflection Layer

16.4 Reflection Pattern

16.5 Shading Layer

16.6 High-efficiency Nano-rod LED Structure

16.7 Other Nano-rod LED Arrangement Structure

17.Repair Technology and Yield Improvement

17.1 Pixel Defect

17.2 Repair Transistor

17.3 Laser Repair

17.4 Conductive Pattern for Repair

17.5 Connection Pattern for Repair

18.Inkjet Equipment

18.1 Inkjet Equipment Composition

18.2 Inkjet Printer Unit

18.3 Sensing Unit

18.4 Electric Field Application Module

19.7T2C TFT Structure and Process

19.1 7T2C TFT and pixel Circuit Structure

19.2 7T2C TFT and Pixel Plane Structure

19.3 7T2C TFT and Pixel Cross-sectional Structure

19.4 7T2C TFT and Pixel Manufacturing Process

Report Sample

Previous Report Status

Related Products

-

QNED Structure and Manufacturing Technology Analysis Report

₩2,500,000May 25, 2020

PDF(61P)UBI Research published a report analyzing Samsung Display’s 41 published patents for QNED (quantum dot nanorod LED). Samsung Display is developing QNED as the next-generation display business. Reports on the QNED structure have already been issued through various channels, but the substance of the QNED has not been released. This report contains directions for the development of QNED technology, including QNED pixel structure and nanorod LED alignment principles analyzed from published patent content. In addition, a manufacturing process constructed based on the structure depicted in the patent was included.

-

QNED Technology Maturity Analysis Report

₩6,000,000June 22, 2021

PDF(271P)The reality of QNED (quantum dot nano-rod LED) that Samsung Display is preparing as a next-generation display has become clear.

As a result of analyzing 160 patents applied by Samsung Display, it was confirmed that the structure constituting the QNED has already been completed, and that the only remaining task is to keep the number of nano-rod LEDs arranged in the light-emitting pixel constant.

The number of aligned nano-rod LEDs per pixel, which determines the yield and image quality of QNED, is determined by the distribution of LEDs in the ink, the number of LEDs injected into the pixel, and the alignment ratio of the injected LEDs. -

Display Application Technology Development Trend of Quantum Dot Report

₩0July 17, 2024

PDF(95P)Quantum Dot (QD) technology is attracting attention in the display industry due to various issues such as utilizing QD films, combining mini LEDs and QD, commercializing Cd-free QD, developing Perovskite QD, and research and development for QD-LED next-generation displays.